inotec barcode labels: secure and reliable

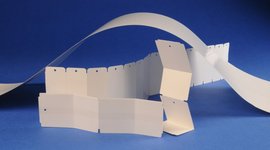

Accurate item control in industry or warehouse, on products or equipment - hardly any area of daily life works without high-quality barcode solutions. Barcodes are a vital tool, to track and gather data on the location and use of countless products. Safe and reliable. Extremely high quality and very long lasting - whenever it comes to precise and individual barcode labelling solutions, inotec is the best partner for every application. Because each barcode label can carry a unique or sequential identity, this offers clear, reliable identification and data. Inotec barcode labels are available in almost every conceivable type, as well as countless shapes and colors - we will offer the best label solution for every application.

The inotec barcode advantage

- Versatile and flexible to use

- Digital printing, thermal transfer

- Hygienic and robust Inmould solutions

- Metal labels for heavy duty applications

- All barcode symbology possible

- Code 2/5 Interleaved, Code 39 and Code 128

- Code EAN 128 or GS1.128 Grayscale in GS1 128

- Datamatrix and GS1 Datamatrix

Secure & precise barcode labelling solutions from inotec

Barcode labelling is a key element for precise identification and efficient processes in numerous industries. inotec is your expert for barcode labels. Our high-quality barcode labelling solutions have been tested under the toughest conditions and have proven themselves millions of times in use.

Whether you need barcode labels for warehouse management, logistics, inventory or other special applications, we always have the right solution. Our barcode labelling products are extremely high quality and particularly durable, so you don't have to worry. Each label is manufactured with the highest precision and enables unique identification.

inotec not only offers you first-class barcode labelling products, but also comprehensive services, from research and production to installation and training. We stand for customised solutions that meet your requirements. Our barcode labelling solutions are made in Germany and meet the highest quality standards.

If you are looking for reliable barcode labels and first-class barcode labelling, inotec is the right place for you. Contact us today to find out more about our customised solutions and work with us to find the right solution for your requirements.

This is where our barcode labels are used

inotec barcode labels are an ideal solution for most standard applications when subjected to light mechanical stress or normal ambient temperatures. The labels are scratch-resistant and can be wiped clean with a damp cloth. Our staff will be happy to help you choose the right barcode label solution for your application.

Our most durables lables

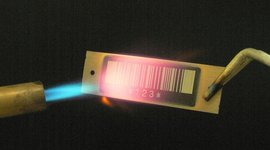

inotec offer the most durable barcode identification solutions in the world. Products developed and adapted to survive extreme conditions under heavy mechanical or chemical pressure. inotec’s labels can reliably withstand high temperatures and are UV-resistant making them a perfect choice inside or outside in areas where other barcoded labels would fail. The labels are an ideal solution for high temperature cleaning, Autoclaves, pressure washing as well as chemical sterilization processes.

Our specialists

If your application demands more, inotec barcode labels for extreme applications are an ideal solution. These are the solutions to rely on when other solutions would fail. In extreme applications in industry, due to mechanical or chemical stresses, extreme temperatures, blast freezing, or kiln operations of up to 1,400 °C, even radiation sterilization processes - inotec extreme barcode solutions can handle it all. The labels provide reliable ongoing barcode identification through extended production processes, recurring aggressive cleaning or even seasonal weather conditions. High quality, extreme durability and lasting reliability.