Everything under control

inotec solutions for warehouse labelling in warehouse logistics

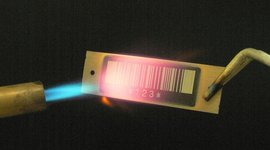

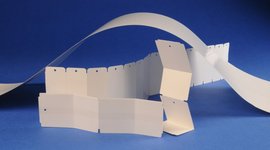

For your high-bay warehouse, block storage, pallet racking or automated small parts warehouse. For shelves, floors or aisles. Regardless of whether you opt for barcodes or advanced RFID storage location labelling - our customised solutions for warehouse labelling in warehouse logistics will take you further.

Why our warehouse labelling solutions?

Our warehouse logistics solutions are designed to meet your specific requirements. Whether you have a high-bay warehouse with complex requirements or a pallet rack with limited space, we have the right solution for you. Our RFID storage location labelling enables precise and real-time tracking of your stock, resulting in a significant improvement in your warehouse management.