Product warnings and recalls are expensive, brand-damaging and sometimes even existentially threatening for the food industry. Producers are liable for any contamination, even if processes, such as transport, are the cause of contamination. Up to now the industry has hardly been able to track how and under what conditions products are being transported. With the new ENFIT standard, an innovative software from bulkvision and highly durable labels from inotec this is now changing.

Case Study: Global traceability in the supply chain

The initial situation

ENFIT was the first international association to establish European and international standards for greater safety and transparency in the supply chain. With an ENFIT certificate, a logistics company can prove that its containers have been hygienically cleaned. For even more safety and global traceability in the supply chain, bulkvision has developed a software with which ENFIT cleaning certificates can also be saved and stored. For the practical implementation, an extremely durable label was required that would allow such information to be saved, stored and easily scanned. The goal was to use the labeling solution to process operations contact-free and to simplify checks and inspections. This results in absolute process transparency which ensures safety for transport companies, certified tank cleaning companies, customers and consumers. Compliance with regulations and EU laws on the transport of foods, thus setting European standards is now an easy task.

The inotec solution

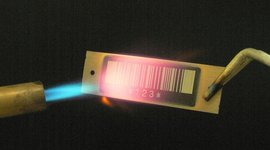

bulkvision is the first traceability system with block chain cloud technology that enables the seamless traceability of foods and allergens as well as the documentation of all process steps in the supply chain. inotec labels of the type Diomaster 175 HPV matt (barcode) or inotec Flex on Metal (RFID) labels, which are certified for the food industry, remain permanently legible and scannable and are not affected by strong weather influences or most harsh cleaning processes. With the aid of a Global Identification Number (GID), which is printed on the label, all containers and transport units can be uniquely identified and can be traced along the entire transport route. Users simply scan the label with the bulkvision app and can read, enter or electronically document data in real time. The result: paperless management, information gain, safety and transparency. The bulkvision software in combination with the inotec labels makes it possible to track & trace when and where which container was cleaned by whom and in compliance with which standards. In the event of contamination the cause can be found much quicker and more reliably.