inotec RFID labels

Whether it's value-added solutions, labels for any item or special applications - when it comes to high-quality RFID labels, inotec is the perfect partner. We always have the right solution. For every use and every challenge. inotec RFID labels are tested under the toughest conditions and are already in use on millions of items - successfully and reliably.

Individually made, comprehensively tested and guaranteed solution-oriented - simply producing labels is too easy for us. At inotec we make sure that you do not have to worry about your labels. From research, manufacturing and installation, to special training and long-term services.

Always individual and always Made in Germany.

Read RFID transponder

RFID transponders have a memory which can be encoded once and locked, or left open and re-encoded multiple times. The memory can then be read out as often as required, carrying the unique identity of the object. In transponders with writable memory, additional information can be saved or data adjusted during use. Basically, a distinction is made between active and passive RFID tags: Passive tags are powered solely by the radio frequency energy of the antenna during the communication process, whereas active tags additionally have a built-in battery.

RFID transponders are available for different frequency ranges:

- Longwave LF at 125-134 kHz

- Shortwave HF at 13.56 MHz

- UHF at 865-869 MHz (European frequencies)

Advantages of RFID technology

The biggest advantage of RFID technology: There is no need for visual contact between the object and the reader. This enables, in addition to a simpler reading of the data, especially pulse readings and acquisitions. Thus, several objects, for example large quantities of marked charge carriers such as reusable containers, can be read out at the same time. This saves a tremendous amount of time for in-store employees as they do not need to scan each bin individually, but automatically and much faster capture using so-called RFID gates. If you are interested in a demonstration of bulk reading, feel free to contact us!

RFID labels - typical application examples

RFID labels can be used in a wide variety of areas. Here are a few examples from industry, commerce, medicine and sport:

- Vehicle identification Personal identification (eg identity card, passport, access control)

- Authentication of medicines

- Labeling of printed circuit boards Textile and clothing industry as well as accessories and jewelery

- Animal Identification

- Inventory Management in Logistics, in Libraries and Archives, in Retail

- Determination of Position in Industry or in Hospital Logistics

- Time Recording ( eg in high-performance sports)

- Waste disposal

- Access and access control

This is where our labels are used

Cost effective RFID smart label solutions from inotec are a perfect choice for less demanding processes or limited trip use. They withstand all the usual light mechanical stress and are ideal for normal temperature environments. They can be wiped clean with a damp cloth, but are not suitable for contact with chemicals or oils. Doe each industry and application, there may be different types of mechanical or environmental factors that need to allowed for - our staff will be happy to explain which inotec solutions will be the right ones for you.

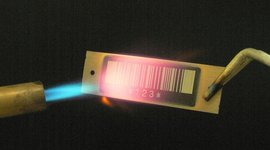

RFID labelling on metal

Some processes demand RFID tags that withstand strong mechanical or chemical stresses – temperature variations and even weathering. inotec offer a wide range of RFID solutions to cope with these special stresses and can withstand a lot more. We have solutions for high temperatures, direct UV radiation and cleaning at high temperatures and under high pressure. This also makes them perfect use outside. Ask our staff which solution is best for you.

Our solutions for special challenges

Special tasks - special solutions. inotec RFID solutions for extreme applications can be used when the durability of conventional labels is no longer sufficient. Whether on-metal, on-ESD or heat-on-metal - inotec has the right solution for every challenge. And if not, we will find one together! Come and discuss your application with us.