Barcode and RFID solutions for automotive and automotive standards

inotec solutions for the automotive industry are safe, convincingly reliable and particularly durable. Even at particularly high temperatures. They are scratch-resistant, light-resistant and also resist oils, light chemicals and acids without any problems. For maximum safety and smooth production. Of course also for the different logistics applications: because inotec inmould and adhesive labels are suitable for all materials from which modern small load carriers (KLT containers) are made. There are also suitable solutions for ESD containers and support for the ISO/IEC and GS1 data standards. They also meet all the requirements of VDA guidelines 4500 and 5501.

THE INOTEC ADVANTAGE

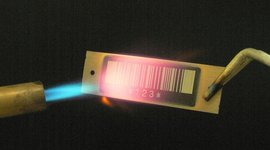

- Ceramic labels, metal labels or foil labels – for mechanical fastening, welding or adhesion

- Temperature ranges up to a maximum of 1,400°C

- Robust and durable data carriers for extreme operating conditions

- Various materials, also available for in-house printing, individual design options

- Thermal transfer, laser engraving and digital printing

- Conforms to VDA guidelines 4500 and 5501

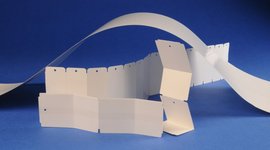

- inmould solutions for maximum durability and safety

- easy integration into the goods cycle

- decades of experience in container management

- bulk readouts possible

Absolutely VDA-compatible

KLT/SLC solutions from inotec are versatile, are always produced individually for you and, of course, meet all the requirements of VDA guidelines 4500 and 5501 without any problems. Thus, as a VDA member, we ensure consistent quality in terms of VDA RFID-KLT (retrofit) and survive all testing or approval procedures with regard to design, material, positioning and functionality of the RFID tags.