Durable industrial labels

Whether in mechanical engineering, the automotive industry, aerospace, or the logistics sector, products with metallic surfaces must be quickly and easily identifiable everywhere! With our OnMetal labels, you have the labels that perfectly match your needs and specific requirements.

Not only extremely resistant to mechanical stress, heat, and weather, but also resistant to oils, chemicals, and acids: Our inotec solutions for the industry impress with their exceptional durability - in every situation. They must, as special challenges require extremely robust and long-lasting data carriers.

The inotec advantage

- Ceramic, metal, or foil labels

- Temperature ranges up to a maximum of 1,400°C

- Robust and durable data carriers for extreme conditions

- For mechanical fastening, burning on as adhesive labels

- Available in various materials, also for self-printing

- Thermal transfer and digital printing

- Personal contacts and long-term support

Made for extreme challenges

When exceptional durability is required, our product solutions are guaranteed to be the best choice. They are always customized to your specific needs and withstand even the most extreme conditions.

Permanent labelling for mechanical stress in industry

Always readable when it matters.

Labels in industrial environments and processes are subjected to very specific conditions. In addition to the strain caused by regular handling, these conditions particularly include mechanical friction arising from transport, usage, and maintenance (cleaning). Industrial barcode and RFID labeling solutions from inotec are specifically designed for these conditions. Ensuring reliable readability and smooth processes even under challenging conditions!

Labelling for applications with harsh cleaning requirements

Made for challenging conditions.

No special treatment required: With inotec solutions for moderate industrial stress, you receive labels that perform excellently in harsh industrial environments. UV exposure is no problem, nor is regular cleaning under high pressure, in ultrasonic baths, or industrial degreasing systems. Even mechanical stress, such as that encountered in conveyor technology or automated processes, pose no obstacle for inotec's industrial labels. Ensuring absolute process reliability even under challenging conditions.

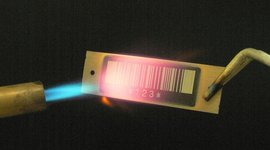

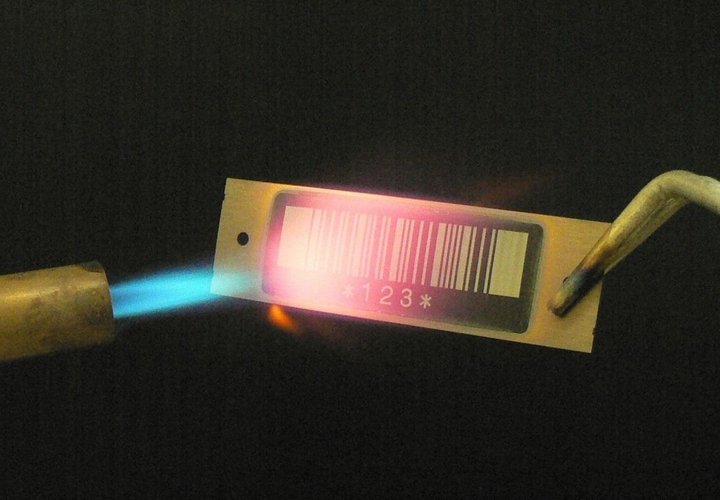

Labelling for extreme industrial environments

Always cool. Even when it gets hot.

Heat, smoke, acids, or alkalis - in extreme industrial environments, labeling solutions face unique challenges. inotec's labels are up to the task. Our barcode and RFID labels thrive even in temperatures up to 1,400 °C. They handle extreme chemical stress such as acids, alkalis, and highly alkaline environments, as well as aggressive surface treatments (e.g., etching baths) and industrial cleanings (e.g., degreasing or ultrasonic baths). This ensures reliable readability, even in the hottest conditions!

Application areas

Permanent labelling is needed wherever products, machines and components have to withstand extreme conditions. Our products offer reliable identification options and guarantee complete traceability.

Labels for workpiece carriers

They can withstand (almost) anything.

Workpiece carriers transport one or more workpieces along a production line through the assigned stations. To be securely controlled and tracked through the process sequence, each workpiece carrier must therefore be permanently equipped with a durable and automatically readable ID.

Particularly challenging: The cyclically recurring load within the process chain requires a permanently readable label that reliably withstands environmental and operating conditions depending on the level of stress. inotec offers customized product solutions for high temperatures, aggressive chemicals, rough, and generally demanding industrial environments. Custom formats or particularly small and high-resolution codes can be produced in collaboration with our Label-Competence-Center.

Labels for tools

Nothing gets lost here.

Workpieces are often processed using tools, work materials, and process resources, either mechanically or manually. Depending on the type and properties of the material or the handling and location of use, the tool is exposed to varying degrees of stress. For this purpose, labels are needed that can withstand not only the stresses of the processing process but also regular cleaning and maintenance. inotec provides customized product solutions specifically for these applications, which can withstand high temperatures, lubricating oils and fats, ultrasonic cleaning, and rugged handling.

Industrial labels for plant and machinery

Safe processes. Perfect results.

Processing, forming, refining: To produce workpieces, many different machines and technical systems are required. To ensure process security, it may be necessary, depending on the degree of automation, to document processing steps or assign workstations. In such cases, a comprehensive and robust plant and equipment labeling system is invaluable. inotec offers durable barcode or RFID solutions that remain permanently readable even in industrial environments and withstand regular wear and tear from operation, use, and maintenance.

Labels for production containers

Safely transported, safely identified.

Containers are indispensable in industrial manufacturing as they transport materials, workpieces, and components of all kinds through various process stages. They must endure a lot during thermal pre- and post-treatment, final processing, assembly, or cleaning in degreasing systems. These cyclically recurring stresses place very high demands on the labeling of baskets, containers, and boxes. Therefore, barcode or RFID solutions are needed that remain permanently readable and reliably withstand environmental and operational conditions.

This is where inotec solutions for industrial containers come into play: They are ideally suited for high temperatures, aggressive chemicals, and harsh and demanding industrial environments, ensuring absolute process reliability.

Labelling conveyor systems and transport units

Always in motion. And yet clearly identifiable.

Large, heavy, bulky: Unwieldy components and workpieces are transported through the process stages in automated systems using racks, pallets, carts, and hooks. A fundamental requirement for this is that the individual transport units must be clearly identifiable to ensure seamless tracking of the process. The harsh and often extreme industrial environment requires not only labels that are particularly durable but also ones that can be reliably read while in motion.

inotec offers exceptionally robust, heat and chemical resistant identification solutions suitable for industrial areas where standard labels do not prevail.

Our cases

Customised identification & labelling solutions for demanding customers

We create customised solutions for your company - and we're happy to show you how! Find out from our references which exciting projects we have already realised for customers.