For more flexibility in warehouse labeling

A little more every day - because to stand still is to fall behind, and we constantly work to become even better. For you. And for our products. This also includes the continuous development of our printing technologies. With our latest investments in new printing processes, we can now offer you even more flexibility.

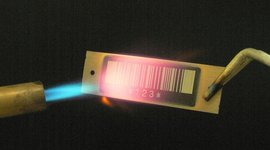

This flexible technology means we can now produce our labels in one continuous flow through one workstation. Because once set up, we can print, die-cut, check and deliver your desired labels directly. This saves production time, increases efficiency and can reduce cost, without compromise of our well know quality. The new printing system not only enables us to print on matt or glossy PP and PE, but also allows high-resolution black on white; for even better barcode contrast and maximum legibility. Due to our extremely adaptable label options, we have a suitable solution for every type of asset in your warehouse; racks, shelves, pallets, crates, dollies and more.

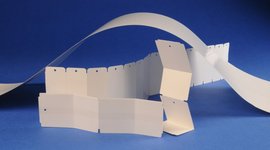

Perfect for shelf manufacturers

The new printing process is not only inexpensive, but also allows us to produce more labels more quickly. With high quality and high resolution. This means that even very large production volumes of single-unit labels with standard dimensions such as 70x200mm can quickly be produced - we can find the perfect size for any crossbeam and, thanks to the sharp contrasts, we achieve optimum legibility. This makes this printing technology the perfect addition to our unique multilevel labels - combine the advantages of both label solutions to maximize warehouse efficiency.

Of course, this new technology can also be used for applications other than in warehouses. Whatever your labeling requirement, inotec has a solution.