For the intelligent marking of warehouse pallet racking

Barcode labels: the intelligent marking of warehouse pallet racking

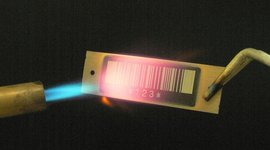

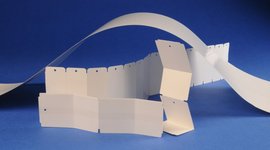

The multilevel label combines the barcode information for all levels of a shelf in one label. The unique design with the inclined barcode fields ensures absolute process reliability. Accidental entry of the wrong storage location is excluded. The print is on the back of the material. This makes the label extremely scratch-resistant and resistant to mechanical stress.

More Info

Barcode label with intelligent colour assignment

Colourcoded Upright and Crossbeam Multilevel barcode labels simplify the management of racking locations in your warehouse.

- Identification of levels using different coordinated colours

- Applied at eye level to uprights or crossbeams for ease of scanning

- No need for long-range scanners

- Excellent scan quality with high definition printing

- Designed for fast accurate barcode scanning from truck mounted readers

- Full installation by inotec technical teams

Directional arrows can be integrated into the layout in order for operators to be able to easily and quickly locate the correct pallets positions in the warehouse racking.

Smart system, through and through

The label is always affixed at sight height on the first crossbar of the label rack. This eliminates the need for costly long-range scanners. This makes it possible to scan labels directly from the forklift without dismounting.

The advantage of working with inotec

- Lower costs for shelf labelling

- Precise reading ability due to slanted barcode

- Minimization of faulty scans

- No design limits thanks to digital printing

- Choice of material depending on stress and substrate

- Robust and resistant to light chemicals

- All commercially available barcodes selectable (also 2D codes)