Label for medical devices

Implementation of the binding UDI guidelines, integration of safety features for absolute counterfeit-proof product protection or consecutive numbering to ensure global traceability - our solutions for medical device labelling, offer complete security. Inotec’s labels not only provide security with regards to applicable EU and UK directives, but also in terms of transparency and complete traceability.

THE ADVANTAGE OF WORKING WITH INOTEC

- Labelling solutions individually adapted to your circumstances

- Clear labelling for the implementation of applicable guidelines

- Tamper-proof labels for maximum product protection

- Serialisation for guaranteed exclusion of duplicate numbers and easy traceability - even globally

- Cloud-based track & trace software connection possible: for easy access from different end devices

- Seamless traceability of all medical devices in real time

- On request: product protection labels in your own design

- Advice, all-round service and long-term support from our experts

Asset management and track & trace in the medical environment

Nothing gets lost here

Always know the current stock status and where your products are currently located - no problem with cloud-based track & trace solutions. You can now map the location of your medical devices in real time. With our serialised barcode and RFID solutions, uncertainty and unpleasant surprises are a thing of the past. Instead, you can seamlessly track where your devices are in use. This prevents bottlenecks as well as unnecessary investments. Larger laboratories, hospitals or hospital groups in particular benefit from this inventory transparency.

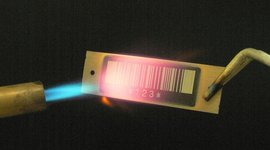

Product protection for the medical and pharmaceutical industry

Play it safe

Damage to image and life-threatening consequences for patients due to the unknowing use of counterfeit products are a growing problem - especially as counterfeit products are becoming increasingly difficult to recognise. With inotec product protection solutions such as inoVerify, you can now guarantee your customers the security they deserve. From various overt or covert security features to tamper-proof labels and serialisation with global traceability - inotec provides you with absolute product protection tailored to your requirements. And, of course, in your design.

The UDI directive for medical devices

When clear labelling becomes mandatory

In future, every medical device will be clearly labelled and therefore identifiable worldwide. This will be done with the help of Unique Device Identification, or UDI for short. At European level, the introduction of this labelling is governed by the Medical Device Regulation (MDR). It was introduced in 2017 and is now gradually coming into force. The regulation uses a risk-based approach for the introduction and implementation, i.e. products in risk class III must be labelled first and products in class I (until 2027) last. This is intended to better ensure patient safety and the traceability of medical devices. To this end, each product is given a product identifier in the form of a numerical code and a barcode or 2D code. The idea behind this: The numerical code is readable by humans, the barcode by machines. If the product is very small, the machine-readable code is also sufficient. The UDI requirements are now an important part of the conformity assessment to obtain CE labelling.

Components of the UDI labelling

UDI-DI & UDI-PI

The UDI consists of two parts: the product identifier (UDI-DI) and the production identifier (UDI-PI).

The former (UDI-DI) is used to identify the product and the manufacturer and must be applied to the product itself and additionally also to its packaging. It is assigned by the responsible allocation body and is static. Up to 20 data points are contained in the identifier, such as information on the trade name, reusability, sterility, etc. The latter (UDI-PI) marks the batch of a product, e.g. lot or batch numbers, serial numbers, expiry and/or manufacturing data and is assigned by the manufacturer itself.

Basic UDI-DI

The basic UDI-DI has a special role. It identifies similar products with the same intended purpose and risk class that differ slightly, for example in engine power. Thus, it is a kind of model identification. Although it functions as a key for the UDI database EUDAMED, it still does not appear on the product or packaging, but is specified by manufacturers with other data elements at the UDI database. Manufacturers must also maintain a list of all assigned UDIs for each medical device. This is part of the technical documentation.

UDI on packaging

Furthermore, as of 2021, manufacturers of medical devices must not only successively mark the products themselves (depending on the class of the medical device), but also their packaging (exception: containers) with the UDI. The following applies here: The code must remain legible throughout the entire service life. This applies to all medical devices.

UDI labelling: important legal requirement, but associated with additional expense

With the UDI Directive, the EU is taking a major step forward in the area of safety for patients in the medical & pharmaceutical sector through clear labelling and complete traceability. Nevertheless, the hurdles for affected manufacturers are not without difficulty and the implementation can hardly be mastered without competent advice and an experienced partner. Our experts will therefore be happy to assist you with any questions and concerns you may have on the subject of labelling with the UDI.